Servo-motor pump drive

Energy-saving drive for the E-Series

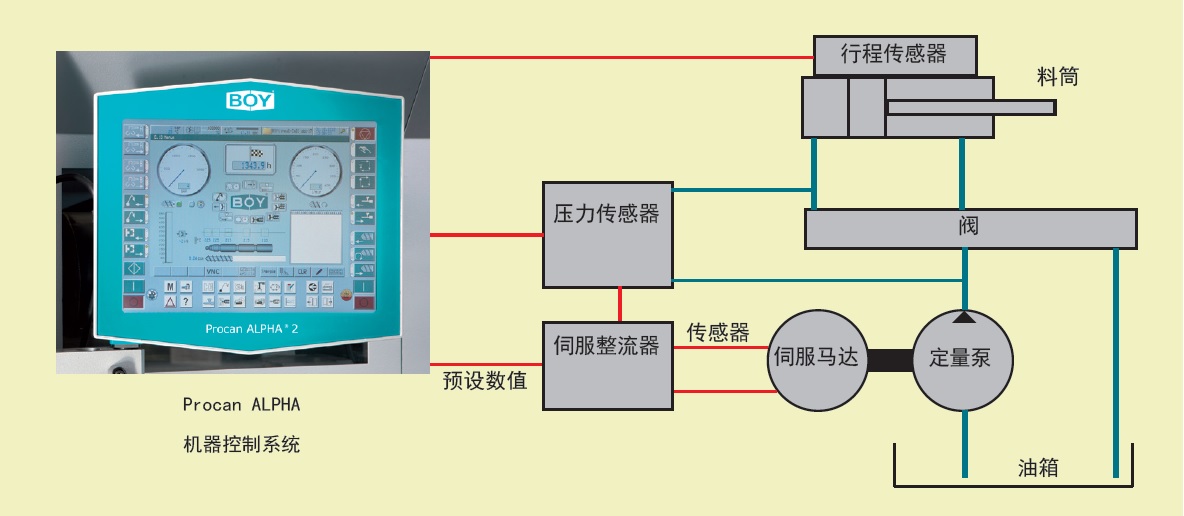

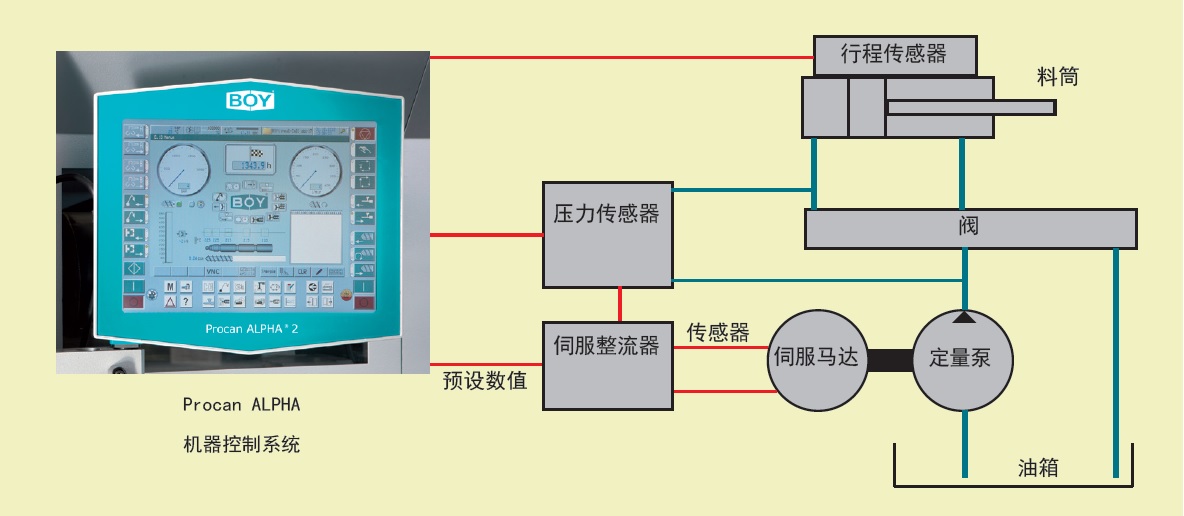

The injection moulding machines of the E-Series are our top models. The essential innovation is the servo-motor pump drive.BOY has always taken the lead in gyefficient solutions. The introduction of the servo-motor pump drive now marks another significant breakthrough in this regard.A gear pump is driven by a special servo motor.Volume and pressure are controlled dynamically by adjusting the motor speed. This means that when neither oil nor pressure are needed, the motor switches off and no longer requires energy.The kinetic energy resulting from the slowing-down is partly stored in the intermediate circuit of the converter and re-used for the next function, e. g. acceleration of an axis.Due to the combined effect of the highly efficient motor and the special converter control,as well as a motor speed adapted to the required volume throughput, the pump always maintains an optimum mode of operation.

The distinctive feature of the system as a whole (converter / motor / pump) is its compact design.

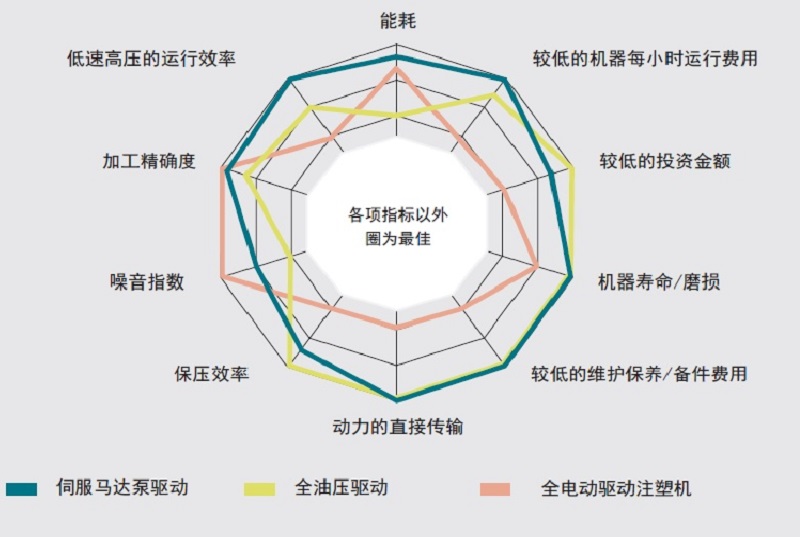

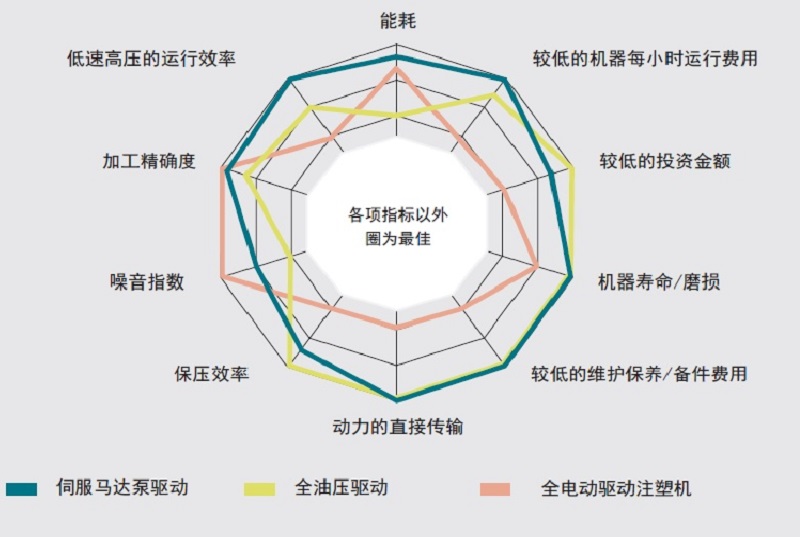

Comparison of drive systems

Distinct advantages for servo-motor pump drive

By using a servo-motor pump drive, it is possible to achieve and even surpass the positive features of electro-mechanical machines, without the disadvantages such as greater investment and spare parts costs and high connected load. Compared to machines with electronically controlled variable displacement pump, the energy consumption of the drive is cut in half. It is even lower than that of electro-mechanical machines which, furthermore, have a markedly higher connected load.This new drive technology also ensures that distinct improvements with regard to noise level,precision, and dynamics are achieved.The noise level is reduced by up to 20 %. This isachieved by:

• Motor speed adapted to the respective situation.Consequently, the inactive motor-pumpunit between end of dosing and end of cooling time is absolutely noiseless.

• Special motor torque control.

• Use of constant delivery pumps.

• Prevention of pressure variations.

• Prevention of sudden changes to movement caused by the switch sequences of the valves.

Improved precision and dynamics are achieved

by:

• Precise consistent acceleration and slowdown performance of the motor-pump unit.

• Response time is 70ms when altering the set value from standstill to full speed and thus to a maximum throughput rate. The reduction of speed is achieved with identical dynamics.

• The optimized motor with high torque features a low moment of inertia, as does the constant delivery pump.

• Converter with high reaction dynamics.

|